I’ve now sent to the printer Peter Nicholson’s “Mechanic’s Companion”; it is scheduled to ship to my driveway in late June, then a few days later out to buyers (just as soon as I train the cats to wrap books…then give up and do it myself).

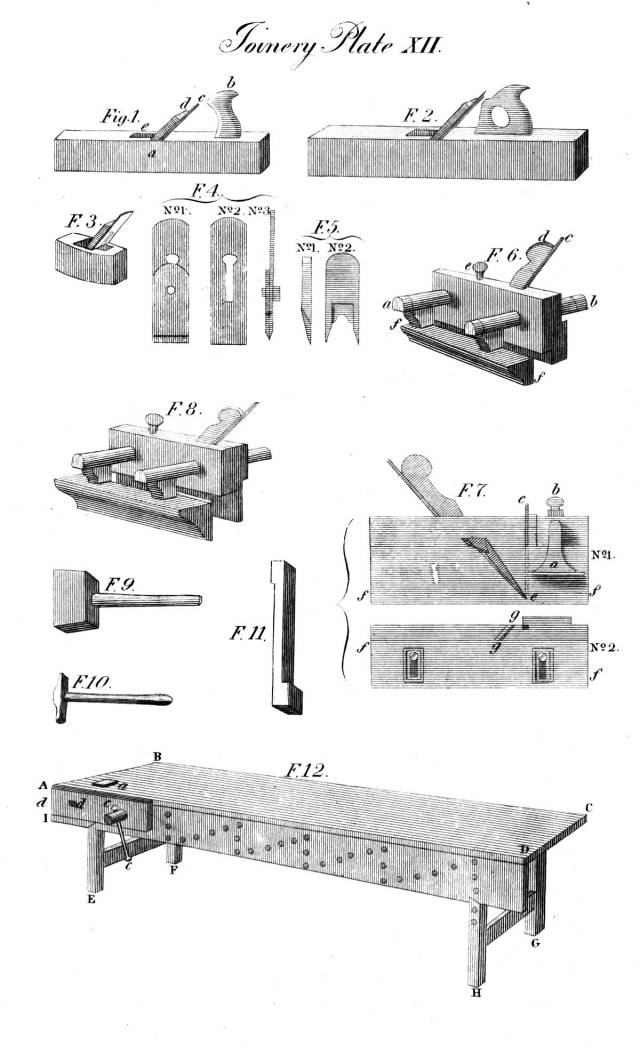

So, the online store for Rude Mechanicals Press (RMP) is now live (please excuse any initial hiccups). My modest goal is to release only a book or two per year for now, all of which will be of high quality and printed in the United States.

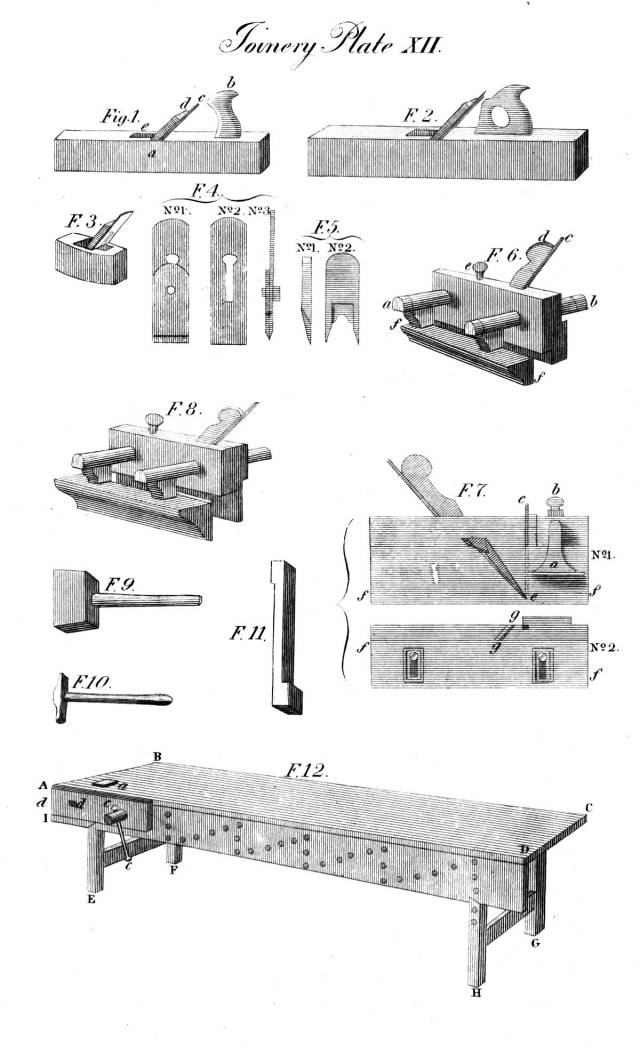

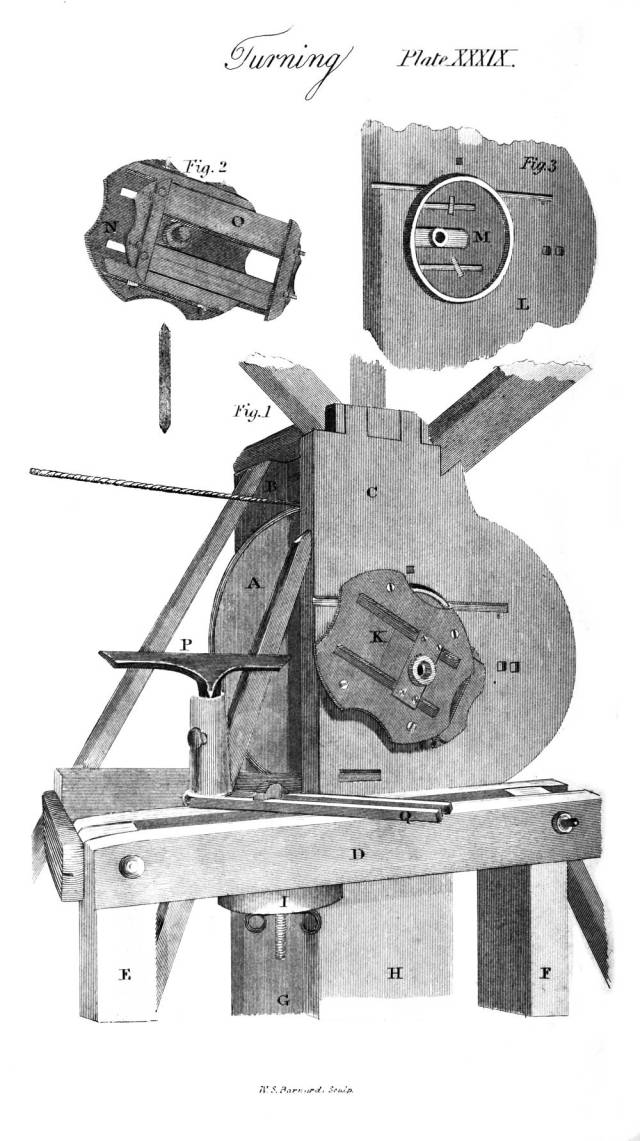

“Mechanic’s Companion” is among the classic tomes (and among the most readable) on woodworking and other building trades in the early 19th century (the first edition was published in 1812). Yet, with the exception of the well-known workbench from Plate 12, it doesn’t get as much attention as other early English technical books. That’s a shame, because it’s an invaluable and thorough treatment of techniques, with 40 plates that provide an excellent and detailed look at the tools of the time, along with a straightforward chapter on the geometry instruction necessary to the building trades.

Nicholson – unlike other technical writers of the time – was a trained cabinetmaker, who later became an architect, prolific author and teacher. So he writes (and writes well) with the authority of experience and clarity on all things carpentry and joinery. For the other trades covered – bricklaying, masonry, slating, plastering, painting, smithing and turning – he relies on masters for solid information and relays it in easy-to-understand prose. (The sections on wood-related trades are by far the most robust.)

There are, of course, online and print-on-demand versions of this book available, but I wanted a well-made, affordable copy that would last, and that one can take into the shop (but that still looks good on the shelf). This one is a scan of an 1845 edition that has been cleaned up in Photoshop, then printed a bit larger than the original for legibility.

This book is 6″x9″, 416 pages and printed on a natural acid-free paper, with just a hint of texture to evoke the look and feel of the original. The interior signatures are Smyth sewn (so the pages are durable but can be opened to relatively flat) and the hard cover is wrapped in cotton cloth and stamped in silver foil. The book is produced and printed entirely in the United States. It is built to last.

The price for Nicholson’s “Mechanic’s Companion” is $34, which includes domestic shipping.

P.S. For now, I cannot ship outside the U.S., but select retailers, including one in the U.K., have expressed interest in stocking this book. Please stay tuned! And know that RMP books will only ever be available direct from me and from reputable partners.

Want to learn some tricks for cutting great dovetails, and build a classic step stool in cherry as you do it? A student had to drop from the “Build a Shaker Step Stool” class at the Lost Art Press storefront/shop July 28-29, so there’s one opening.

Want to learn some tricks for cutting great dovetails, and build a classic step stool in cherry as you do it? A student had to drop from the “Build a Shaker Step Stool” class at the Lost Art Press storefront/shop July 28-29, so there’s one opening.

Fig. 11 the square, a b c the outer square, d e f the inner square, a d e the stock or handle, b c f e the blade.

Fig. 11 the square, a b c the outer square, d e f the inner square, a d e the stock or handle, b c f e the blade.