Apologies in advance to my Thanksgiving guests for the mess – which is going nowhere before Thursday.

As think forward to my front staircase renovation (the bulk of which will come after the sink build), I’m thankful I don’t have to rebuild them from scratch. Still, Peter Nicholson’s words ring true: “…for any error, however small, when multiplied, becomes of considerable magnitude, and even the difference of an inch in the last riser, being too high or too low, will not only have a bad effect to the eye, but will be apt to confound persons not thinking of any such irregularity.”

In other words, if you muck it up, folks will trip – and it is indeed the last (or first, depending on your starting point) riser that’s in play. I have to cut three stringers for the bottom steps, find 1-1/2″-thick 100-year-old Southern yellow pine (60′” long times two) … and I have to do that part soon. (The rail and baluster will continue to wait.)

My temporary steps have never been supported at the left end; that extra bit out there is just to help me envision how they will wrap to a built-in bookcase at the front edge of the landing (the paint samples that block that area actually serve a safety function…in addition to displaying my laziness!). And the right end isn’t fully supported, either; the stringer there was either modified during the 1950s remuddling, or it supported a narrow curved return on the bottom stair in the original layout – because it stops well short of the front edge of the tread. So my temp tread has now split.

I know where it’s safe (relatively speaking) to step, so I don’t worry too much about it. But two weeks ago, when Christopher Schwarz helped me fetch, carry and place the hallway built-in carcases, I had horrid visions of one end or the other of that bottom tread snapping off, sending him first to the ground, then to the hospital (though in hindsight, I probably should have worried more about our backs).

So before that sink base build (because I do not wish to maim my friends), I’ll at least be making those bottom stringers and affixing the permanent treads (drop me a line if you have any thick, long, antique yellow pine available).

In the meantime (still), all guests must use the back stairs (of, according to Nicholson, the “inferior kind” of dog-leg construction), up which the built-in carcases would have never fit.

The back stairs also need work – but it’s all cosmetic.

Below is an excerpt from the staircase joinery section of “Mechanic’s Companion,” which explains the difference between “bracket stairs” (my front ones) and “dog-legged” (my back ones). He also writes about “geometrical stairs” – the kind that are far too fancy for my house!

———–

§87. Stairs.

Stairs are one of the most important things to be considered in a building, not only with regard to the situation, but as to the design and execution: the convenience of the building depends on the situation; and the elegance on the design and execution of the workmanship. A staircase ought to be sufficiently lighted, and the head-way uninterrupted. The half paces and quarter paces ought to be judiciously distributed. The breadth of the steps ought never to be more than fifteen inches, nor less than ten; the height not more than seven, nor less than five; there are cases, however, which are exceptions to all rule. When you have the height of the story given in feet, and the height of the step in inches, you may throw the feet into inches, and divide the height of the story in inches by the height of the step; if there be no remainder, or if the remainder be less than the half of the divisor, the quotient will show the number of steps; but if the remainder be greater than the half of the divisor, you must take one step more than the

number shown by the quotient: in the two latter cases, you must divide the height of the story by the number of steps, and the quotient will give the exact height of a step: in the first case, you have the height of the steps at once, and this is the case whatever description the stairs are of. In order that people may pass freely, the length of the step ought never to be less than four feet, though in town houses, for want of room, the going of the stair is frequently reduced to two feet and a half.

Stairs have several varieties of structure, which depends principally on the situation and destination of the building. Geometrical stairs are those which are supported by one end being fixed in the wall, and every step in the ascent having an auxiliary support from that immediately below it, and the lowest step, consequently from the floor.

Bracket stairs are those that have an opening or well, with strings and newels, and are supported by landings and carriages, the brackets mitering to the ends of each riser, and fixed to the string board, which is moulded below like an architrave.

Dog-legged stairs are those which have no opening or well-hole, the rail and balusters of both the progressive and returning flights fall in the same vertical planes, the steps being fixed to strings, newels and carriages, and the ends of the steps of the inferior kind, terminating only upon the side of the string, without any housing. …

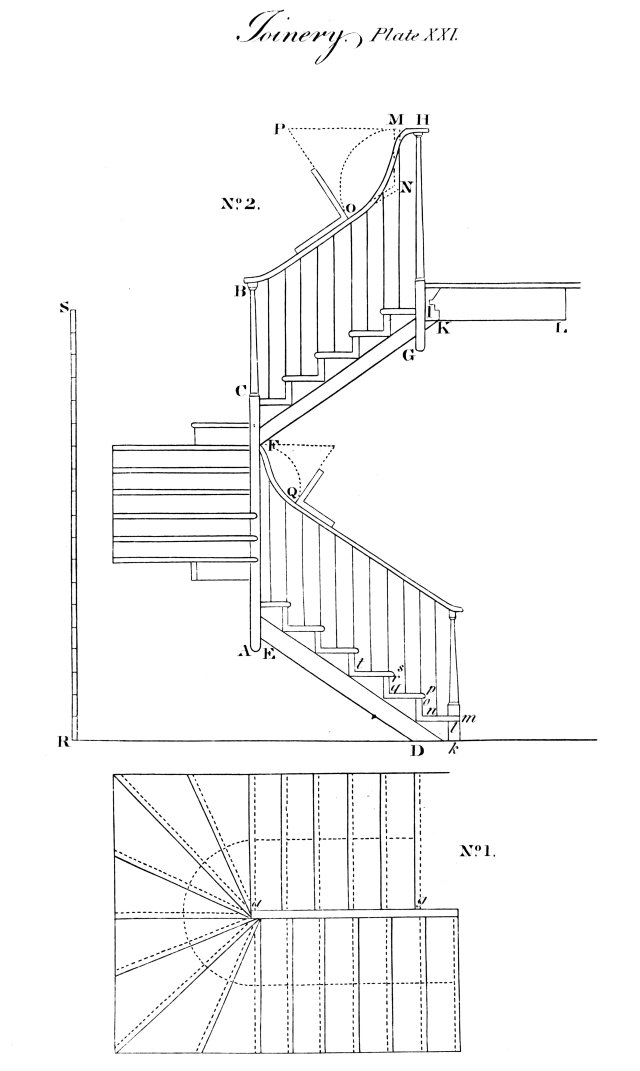

PLATE XXI.

EXPLANATION,

Showing the Construction of a Dog-leg Staircase

No. 1. the plan,

No. 2. the elevation.

A B, No. 2. the lower newel, the part B C being turned

a No. 1. the seat of the newel on the plan.

G H, No. 2. the upper newel.

g, No. 1. its seat on the plan.

D E and F G, No. 2. lower and upper string boards framed into the newels.

K L, No. 2 a joist framed into the trimmer I.

k l, n o, q r, & c. No. 2. the faces of the risers; m n, p q, s t, the treads of the cover boards.

m, p, s, &c. No. 2. the nosings of steps.

The dotted lines on the plan, represent the faces of the risers; and the continued lines, the nosings of the steps.

M O and F Q, upper and lower ramps.

The method of drawing the ramp is as follows: suppose the upper ramp to be drawn; produce the top H M of the rail to P draw M N perpendicular to the horizon, and produce the straight part O N of the pitch of the rail, to meet it in N; making N O equal to N M : draw O P at right angle to O N: from P as a centre, describe the arc M O, and then the other concentric circle, which will complete the ramp required.

R S the story rod ; a necessary article in fixing the steps, for if put up only by a common measuring rule, will frequently occasion an excess or defect in the height, so as to render the stair extremely faulty, which cannot be the case, if the story rod is applied to every riser, and the riser regulated thereby. In the aforesaid case, the error is liable to multiply.

I can’t use my bench at Lost Art Press this weekend because we’ve a class going on. I came across the river with thoughts of getting started on the drawers for my built-in – I can mill stock and cut it to size in the machine shop without disturbing the class.

I can’t use my bench at Lost Art Press this weekend because we’ve a class going on. I came across the river with thoughts of getting started on the drawers for my built-in – I can mill stock and cut it to size in the machine shop without disturbing the class.